Why 6082-T6 Aluminum Forging Is Ideal for Motorcycle and Bicycle Parts

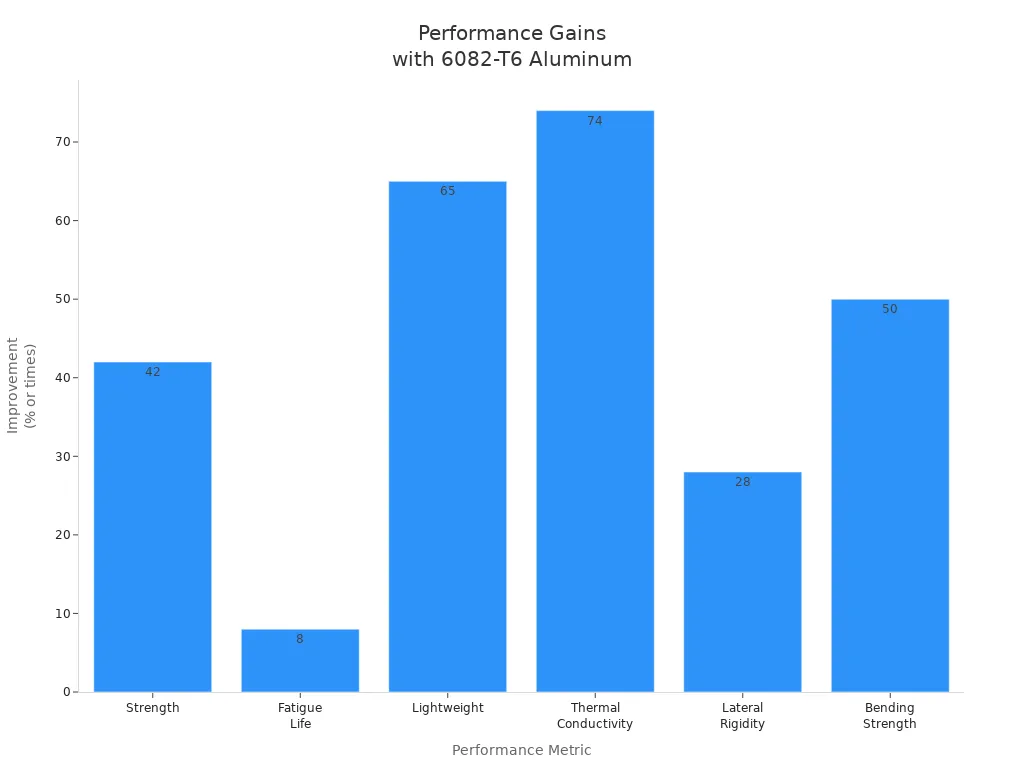

6082-T6 Aluminum Forging stands out as the material of choice for motorcycle and bicycle parts. Riders value unmatched strength, durability, and lightweight construction. Manufacturers rely on its corrosion resistance and thermal conductivity to deliver reliable products. The following table highlights key performance metrics that improve when using this alloy:

Metric | Improvement Description |

|---|---|

Strength | Tensile strength of 6061-T6 forged aluminum reaches 310MPa, which is 42% higher than that of the cast state. |

Fatigue Life | In a 2 million cycle load test, the crack initiation time of forged aluminum is extended by 8 times. |

Lightweight | The density is only 2.7g/cm³, which is 65% lighter than steel. |

Thermal Conductivity | 167W/m·K, which is better than the 96W/m·K of cast aluminum. |

Lateral Rigidity | Forged aluminum hub increases lateral rigidity by 28%. |

Bending Strength | Bending strength increased by 50% for pedal shafts. |

Choosing the right material ensures higher performance and longer-lasting parts for every ride.

6082-T6 Aluminum Forging Strength

Mechanical Strength

6082-T6 Aluminum Forging delivers superior mechanical strength, making it a top choice for motorcycle and bicycle parts. The alloy stands out due to its elevated manganese content, which directly boosts its strength and hardness. Manganese levels in this alloy range from 0.4% to 1.0% by weight. This addition increases the alloy’s ability to handle high-stress applications and provides the highest strength among the 6000 series aluminum alloys. As a result, manufacturers often select it for structural components that demand reliability.

The following table compares the mechanical properties of 6082-T6 Aluminum Forging with other commonly used aluminum alloys in the transportation industry:

Alloy | 6082 T6 | Other Alloys |

|---|---|---|

Tensile strength (MPa) | ≥340 | ≥290 |

Specified non-proportional tensile strength (MPa) | ≥300 | ≥250 |

Elongation after break (%) | ≥10 | ≥5 |

Brinell hardness (HBW) | ≥90 | ≥90 |

Note: Higher tensile strength and elongation values mean that 6082-T6 Aluminum Forging can withstand greater forces and deformation before breaking, which is essential for safety and performance.

Fatigue Resistance

Forged 6082-T6 aluminum parts show remarkable resistance to fatigue, which is the gradual weakening of a material caused by repeated loading and unloading. The forging process creates a fine-grained microstructure that plays a critical role in this property. Research shows that this uniform grain structure suppresses abnormal grain growth, leading to improved mechanical properties and enhanced fatigue resistance. This homogeneity reduces the risk of crack formation, which means parts last longer and perform better under continuous stress.

Key benefits of the fine-grained microstructure:

Increases durability by minimizing weak points where cracks can start.

Enhances the overall lifespan of motorcycle and bicycle components.

Provides consistent performance even in demanding riding conditions.

6082-T6 Aluminum Forging offers a unique combination of high strength and excellent fatigue resistance. Riders and manufacturers can trust these parts to deliver reliable performance over time, even when exposed to challenging environments and repeated use.

Lightweight Performance

Handling & Speed

Motorcycle and bicycle enthusiasts often seek parts that improve handling and speed. 6082-T6 Aluminum Forging offers a significant advantage in this area. The alloy’s lightweight nature allows manufacturers to reduce the overall weight of vehicles without sacrificing strength or safety. Riders experience better control and responsiveness, especially during sharp turns or high-speed maneuvers. The combination of strength and lightness makes this material ideal for high-performance models.

Lightweight and strong properties enhance motorcycle performance.

Excellent strength and resistance to wear and tear.

Ability to bear high loads and intense impacts ensures safety in high-speed racing.

Combines strength and lightness for high-performance models.

A lighter frame and components mean less inertia, which leads to quicker acceleration and shorter stopping distances. Riders benefit from improved agility and confidence on the road or track. The reduced weight also helps maintain stability, making it easier to navigate challenging terrain.

Tip: Choosing lightweight forged aluminum parts can transform the riding experience by making vehicles more responsive and easier to handle.

Efficiency

Efficiency remains a top priority for both riders and manufacturers. 6082-T6 Aluminum Forging contributes to this goal by reducing the total weight of motorcycles and bicycles. Studies show that replacing steel components with aluminum alloy components can reduce the total weight of a vehicle by 30%-40%. This significant reduction leads to improved fuel efficiency and overall performance.

The lightweight nature of 6082-T6 aluminum reduces the overall weight of vehicles.

A decrease in vehicle weight leads to a reduction in the driving force required.

Lower driving force results in decreased energy consumption during operation.

Lightweight components also enhance safety by reducing inertia, leading to shorter stopping distances.

Manufacturers value these benefits because they align with the industry’s focus on environmental sustainability. Riders appreciate the cost savings from reduced fuel consumption and the increased reliability of their vehicles. The efficiency gains from using lightweight forged aluminum parts support longer rides and better performance.

Corrosion Resistance

Weather Protection

Motorcycle and bicycle parts face constant exposure to rain, mud, and road salts. 6082-T6 Aluminum Forging provides outstanding protection against these elements. Laboratory tests, including exposure, potentiodynamic, and Audi tests, have demonstrated the alloy’s ability to resist corrosion. Researchers used stereo, optical, and scanning electron microscopy, along with energy dispersive spectroscopy, to evaluate the surface and internal structure. These methods revealed minimal degradation, even after prolonged exposure.

The alloy maintains its appearance and function in wet and salty environments.

Components resist pitting and surface damage, which often affect other metals.

Riders experience fewer maintenance issues related to rust or corrosion.

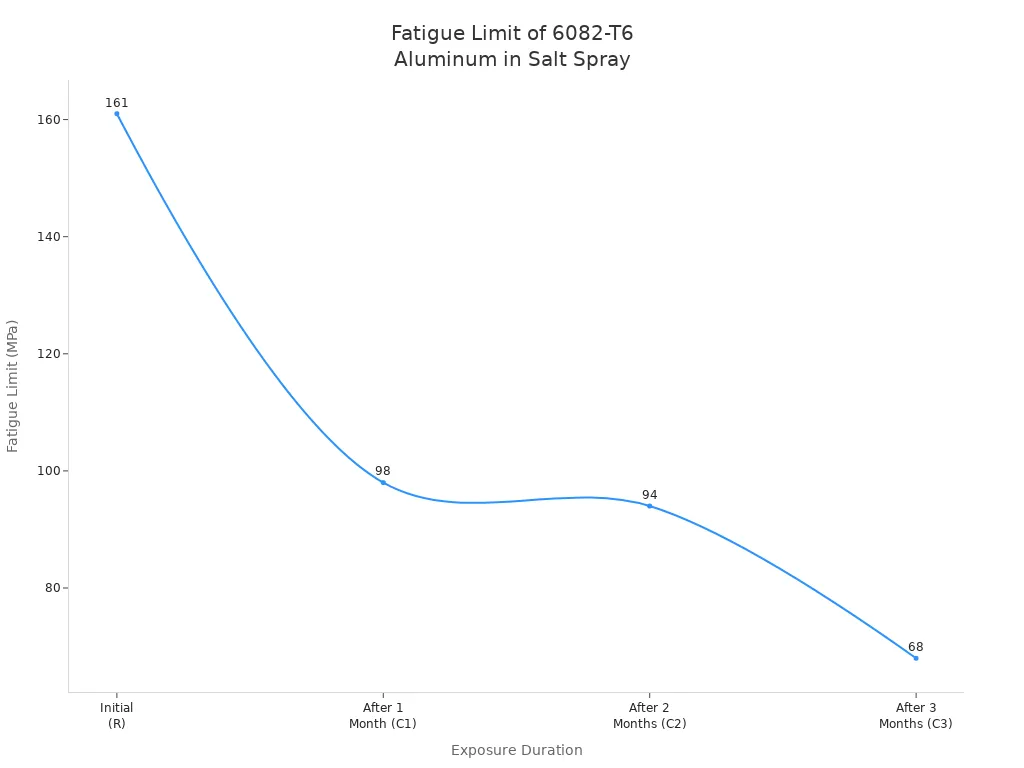

Salt spray tests further highlight the durability of 6082-T6 Aluminum Forging. The following table shows how the fatigue limit changes after exposure to harsh conditions:

Exposure Duration | |

|---|---|

Initial (R) | 161 |

After 1 Month (C1) | 98 |

After 2 Months (C2) | 94 |

After 3 Months (C3) | 68 |

Even after months of exposure, the alloy retains much of its strength, which is crucial for safety and reliability.

Longevity

Long-term reliability matters for every rider and manufacturer. 6082-T6 Aluminum Forging excels in this area by maintaining structural integrity over years of use. The forging process improves corrosion resistance, making components suitable for extreme conditions. This advantage ensures that parts last longer and perform consistently.

Property | Description |

|---|---|

Aluminum has great corrosion resistance, which is improved in forging, making components useful in extreme conditions. |

Improved durability against environmental factors

Maintains structural integrity of components

Essential for performance in harsh conditions

Motorcycle and bicycle parts made from this alloy show fewer signs of wear and tear. Riders benefit from reduced replacement costs and increased confidence in their equipment. Manufacturers value the extended lifespan, which supports sustainability and customer satisfaction.

Choosing materials with high corrosion resistance leads to safer, longer-lasting vehicles.

Machinability & Design

Precision

Manufacturers often choose 6082-T6 Aluminum Forging for its outstanding machinability and ability to achieve tight tolerances. This material supports the creation of intricate parts that require exact dimensions. In the T6 temper, machinists notice excellent chip formation and less tool wear, which leads to smoother surfaces and more accurate results. These qualities make it possible to produce components that fit together perfectly and perform reliably under stress.

6082-T6 Aluminum Forging allows for the production of complex shapes with high precision.

The alloy maintains strength and durability even in detailed designs.

Machinists experience reduced tool wear, which helps maintain accuracy over long production runs.

The material’s balance of strength, corrosion resistance, and machinability ensures that finished parts meet strict quality standards.

Precision in manufacturing means that every part functions as intended. Riders and manufacturers both benefit from components that deliver consistent performance and safety.

Flexibility

Design flexibility stands out as another major advantage of 6082-T6 Aluminum Forging. The forging process enables the creation of custom shapes and sizes that meet specific needs. Engineers can design lightweight frames, intricate brackets, or unique hubs without sacrificing strength or reliability. This adaptability supports innovation in both motorcycle and bicycle industries.

Forging allows for easy customization of parts to fit different models and uses.

The process supports the production of both small and large components with equal efficiency.

Designers can experiment with new forms, knowing the material will maintain its integrity.

Note: The ability to customize shapes and sizes helps manufacturers respond quickly to changing trends and rider preferences.

With these benefits, 6082-T6 Aluminum Forging remains a top choice for those who demand both precision and flexibility in their components.

Applications & Value

Motorcycle Parts

Manufacturers rely on 6082-T6 Aluminum Forging to produce a wide range of motorcycle components. This alloy offers high strength and durability, which are essential for parts exposed to constant stress and vibration. Common applications include:

Frames: The main structure of the motorcycle benefits from the alloy’s strength and lightweight properties. Riders experience improved handling and stability.

Wheel Hubs: Forged aluminum hubs increase lateral rigidity, which enhances control during cornering.

Brake Calipers: These components require precise machining and resistance to corrosion. The alloy’s machinability allows for intricate designs that maintain performance over time.

Handlebars and Foot Pegs: These parts must withstand repeated impacts and fatigue. The fine-grained microstructure of forged aluminum helps prevent cracks and extends service life.

Suspension Components: Forks and swingarms made from this alloy offer a balance of strength and weight, improving ride comfort and safety.

Motorcycle manufacturers choose 6082-T6 Aluminum Forging for its ability to deliver reliable, high-performance parts. Riders benefit from reduced weight, increased durability, and lower maintenance costs.

Bicycle Components

Bicycle designers also favor 6082-T6 Aluminum Forging for critical components. The alloy’s lightweight nature and corrosion resistance make it ideal for parts that face outdoor conditions and frequent use. Key examples include:

Frames: Lightweight frames help cyclists achieve faster speeds and easier maneuverability. The alloy’s strength ensures safety during intense rides.

Pedal Shafts: Forged aluminum pedal shafts offer increased bending strength, which supports efficient power transfer.

Cranksets: These parts require both precision and durability. The alloy’s machinability allows for complex shapes that fit together seamlessly.

Wheel Rims and Spokes: Reduced weight in these components improves acceleration and climbing ability.

Seat Posts and Stems: Corrosion resistance ensures these parts remain reliable even after exposure to rain and mud.

Bicycle manufacturers value the alloy’s ability to produce components that combine performance with longevity. Cyclists enjoy smoother rides and fewer replacements.

Cost-Effectiveness and Sustainability

6082-T6 Aluminum Forging supports sustainable manufacturing practices and cost savings. The forging process minimizes material waste by optimizing material flow in the die. Manufacturers achieve high precision, which reduces the need for post-processing operations and lowers production costs.

The recyclability of aluminum stands out as a major environmental benefit. Recycling aluminum requires only about 5% of the energy needed for primary production. This process maintains the alloy’s properties, allowing manufacturers to reuse materials without sacrificing quality.

The following table summarizes the sustainability advantages:

Benefit | Description |

|---|---|

High Precision | Enables the production of components with minimal need for post-processing operations. |

Minimal Material Waste | The forging process minimizes material waste through optimal material flow in the die. |

High Strength | Aluminum alloy provides desirable properties for achieving high strength in components. |

Corrosion Resistance | The material’s inherent properties contribute to its resistance against corrosion. |

Recyclability | 6082-T6 aluminum is recyclable, supporting sustainable manufacturing practices. |

Manufacturers use solid state recycling methods, such as cleaning aluminum chips and direct extrusion, to further reduce energy consumption and material waste. These methods eliminate the remelting phase, which saves energy and preserves mechanical properties. Recycled 6082-T6 aluminum chips can match the performance of commercially produced alloys.

Aluminum maintains its properties through recycling.

Environmental impacts from recycling are much lower than those from primary production.

Solid state recycling enhances energy and material savings.

Motorcycle and bicycle industries benefit from these practices by reducing costs and supporting environmental goals. Riders and manufacturers both contribute to a more sustainable future by choosing components made from 6082-T6 Aluminum Forging.

6082-T6 Aluminum Forging stands out in the motorcycle and bicycle industries for several reasons:

Low weight helps create lighter vehicles for better speed and handling.

Corrosion resistance protects parts from harsh weather and road conditions.

Excellent mechanical properties support reliable and high-performance components.

High strength forging process and wide applicability meet the needs of demanding riders.

Manufacturers use this alloy for stems, hubs, pedals, and cranksets, taking advantage of its strength and formability. Riders and builders can trust this material for durable, efficient, and advanced parts.

FAQ

What makes 6082-T6 aluminum forging better than casting for bike and motorcycle parts?

Forging creates a fine-grained structure. This process increases strength and fatigue resistance. Cast parts often show more defects and lower durability. Riders and manufacturers prefer forged components for reliability.

Can 6082-T6 aluminum forged parts be recycled?

Yes, manufacturers recycle 6082-T6 aluminum easily. The recycling process uses less energy than producing new aluminum. Recycled parts maintain high strength and corrosion resistance. This supports sustainability in the industry.

Does 6082-T6 aluminum resist rust in wet conditions?

6082-T6 aluminum resists corrosion well. The alloy forms a protective oxide layer. This layer shields parts from moisture and road salts. Riders see fewer rust problems and longer-lasting components.

Are forged 6082-T6 aluminum parts heavier than carbon fiber?

Forged 6082-T6 aluminum parts weigh more than carbon fiber. However, they offer higher impact resistance and easier repair. Manufacturers choose aluminum for parts that need strength and durability.

Which motorcycle and bicycle parts use 6082-T6 aluminum forging most often?

Manufacturers use 6082-T6 aluminum forging for frames, hubs, pedal shafts, cranksets, and suspension components. These parts benefit from the alloy’s strength, light weight, and corrosion resistance.